I

am reposting these 2 articles from Nanowerk. Just from a breath sensor

your behaviors can be accurately monitored. And AI can now 3 D print

your food. Welcome to Technocracy. Are you keeping up or are you

experiencing Future Shock?

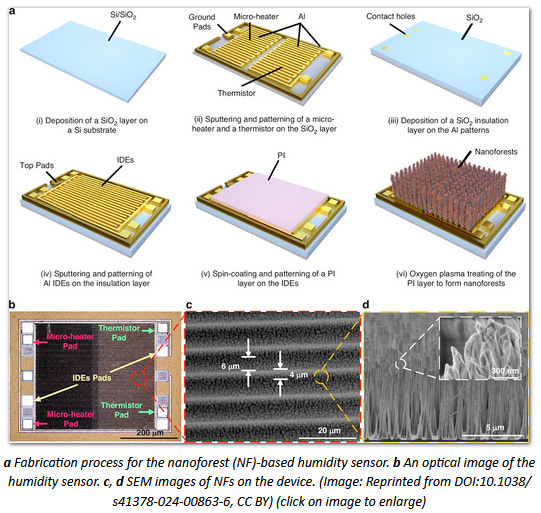

Nanostructured humidity sensor achieves 96% accuracy in identifying human behaviors through breath analysis

(Nanowerk Spotlight)

Each exhaled breath carries distinct signatures of human activity -

quick and shallow during exercise, deep and regular in sleep, irregular

while speaking. These breathing patterns provide a window into behavior,

but capturing and interpreting these subtle respiratory variations has

challenged scientists and engineers. Camera systems can track physical

movements but miss physiological nuances. Wearable devices require

multiple sensors that increase bulk and complexity. Traditional humidity

sensors, while promising for breath detection, lack the sensitivity and

response speed (around 2.2 seconds for recovery in this sensor)

required to capture rapid moisture changes in exhaled air. The technical

challenge lies in detecting minute humidity variations quickly enough

to map them to specific behaviors. Chinese researchers have engineered a

solution: a humidity sensor that uses microscopic "nanoforests" to

detect subtle changes in breath moisture. Published in Microsystems & Nanoengineering ("An intelligent humidity sensing system for human behavior recognition"),

their system combines these specialized structures with precise

temperature control to achieve 96.2% accuracy in distinguishing between

nine different human behaviors. The sensor's nanoforests create an

extensive surface area covered in hydrophilic groups - molecular

structures that readily interact with water molecules. Elevated

operating temperatures further increase the activity and diffusion speed

of these molecules, significantly boosting sensor sensitivity. When a

person exhales, water vapor from their breath adheres to these surfaces

through hydrogen bonding, forming initial chemical bonds. As humidity

increases, additional water molecules stack onto this first layer

through weaker physical bonds, creating multiple layers that the sensor

can detect.

A

built-in micro-heater maintains the sensor at 57.1°C, increasing its

sensitivity by nearly six times compared to room temperature operation.

This enhancement allows detection of even slight variations in breath

moisture. An integrated thermistor continuously monitors temperature,

providing additional data about breathing patterns. The system processes

this combined humidity and temperature data through a machine learning

algorithm that converts the measurements into two-dimensional maps.

These maps serve as input for a neural network trained to recognize

specific behaviors. The researchers tested the system's

ability to identify nine distinct states: working, speaking, walking,

playing electronic games, sleeping, sighing, breath holding, jumping,

and exercising. The results demonstrated perfect recognition of five

behaviors - working, walking, sleeping, sighing, and breath holding. The

system occasionally confused similar activities, such as misclassifying

jumping as exercise due to comparable breathing patterns. Speaking was

sometimes mistaken for gaming activity, likely due to overlapping

respiratory characteristics. The sensor maintained consistent

performance through more than 1,000 consecutive breathing cycles,

demonstrating robust stability. It also showed high selectivity for

water vapor compared to other breath components like oxygen, carbon

dioxide, and nitrogen, ensuring accurate humidity measurements even in

complex respiratory environments. The researchers

integrated their sensor into a face mask that wirelessly transmits

breathing data to smartphones or computers for real-time analysis. This

implementation enables continuous behavior monitoring without requiring

multiple devices or complex setups.

The

technology offers particular utility in healthcare settings, where

automated behavior tracking could help monitor patient activity levels

and sleep patterns. In smart homes, the system could adjust

environmental controls based on detected behaviors. The

non-invasive nature of humidity sensing preserves privacy while

providing detailed insights into physical and physiological states. The

sensor's ability to extract behavioral information from breath moisture

represents a shift in human activity monitoring. By focusing on this

single, information-rich parameter, the system achieves sophisticated

behavior recognition without the complexity of multiple sensor types or

the privacy concerns of video monitoring. The research demonstrates how

precise measurement of a fundamental physiological process - breathing -

can reveal complex patterns of human behavior. This

technical advancement brings automated behavior recognition closer to

practical implementation in healthcare and daily life applications.

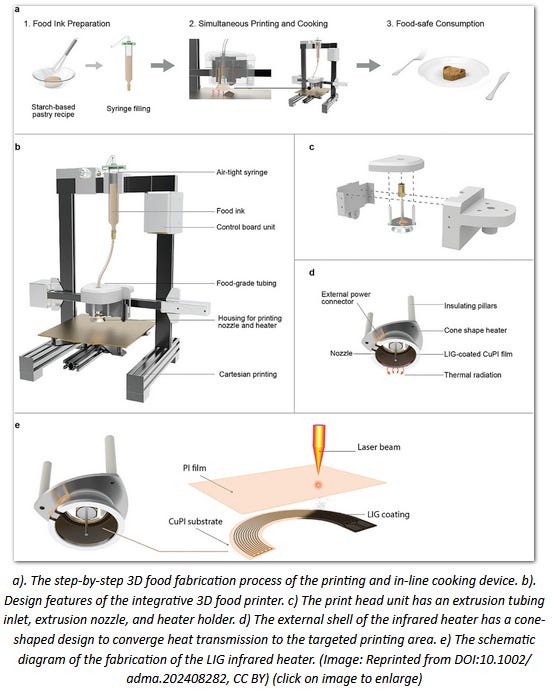

AI-powered 3D printer cooks food in real-time, automating commercial food prep

(Nanowerk Spotlight)

A new 3D printer can cook food layer by layer as it prints, using

artificial intelligence to design complex edible structures. This

integrated system, developed at Hong Kong University of Science and

Technology, combines precision infrared heating with AI-driven design

tools to address key limitations in automated food production:

maintaining food safety during printing and creating intricate shapes

without requiring technical expertise. The findings have been reported

in Advanced Materials ("Advanced 3D Food Printing with Simultaneous Cooking and Generative AI Design").

Automated food production faces unique challenges compared to

manufacturing with traditional materials like plastics or metals. Food

must be heated properly to ensure safety, yet maintaining the intended

shape during cooking proves difficult. Current 3D food printers operate

in two separate steps - first printing cold food paste, then

transferring it to an oven or fryer. This approach often leads to

deformed shapes and increased contamination risks as the food moves

between machines. The new system integrates these steps using a

specialized infrared heater made from laser-treated polyimide film,

known as laser-induced graphene (LIG). This ultra-thin heating element

provides precise temperature control, with printed food layers reaching

137°C on the surface and maintaining at least 105°C on the sides

throughout the printing process, while using just 14 watts of power - a

fraction of the 1000-2000 watts consumed by conventional ovens and air

fryers.

The

researchers demonstrated their printer using starch-based cookie dough.

As each layer of dough emerges from the printing nozzle, the infrared

heater immediately cooks it, maintaining the exact printed shape while

killing harmful bacteria. This immediate cooking prevents the slumping

and deformation that typically occurs when printed food items wait to be

baked. Detailed analysis revealed superior results compared to

conventional cooking methods. Using scanning electron microscopy, the

team observed that infrared-cooked samples maintained consistent

internal structure without the dramatic swelling seen in oven-baked

items. X-ray imaging showed uniform porosity throughout the food,

indicating thorough cooking without compromising structural integrity.

Additionally, COMSOL simulations confirmed even heat distribution,

showing that heat penetrated only 1-2 mm from the top layer, preventing

overcooking of the lower layers. The system's food safety advantages

became clear through bacterial testing. While conventionally cooked

samples showed substantial bacterial growth after 48 hours,

infrared-treated items had only 0-6 bacterial colonies at 100°C,

compared to over 200 colonies in oven-baked and air-fried samples. This

improvement stems from the immediate high-temperature treatment of each

printed layer. The researchers also simplified the design process

through artificial intelligence. Instead of requiring users to master

complex 3D modeling software, their system accepts simple text

descriptions. These descriptions feed into the DALL-E AI system, which

generates appropriate 2D images. A custom Python script then converts

these images into STL 3D modeling files, making them ready for printing

without additional user intervention. A baker could type "gingerbread

man with detailed pattern" and receive a complete, printable design

within minutes. Testing demonstrated the system's versatility. The

printer successfully created items with intricate perforated patterns

and multiple layers while maintaining precise dimensional accuracy.

Beyond cookie dough, it handled various food materials, including

vegetable purees and protein-based ingredients, further validating the

system’s adaptability to different food types. The technology's

implications extend beyond simple food printing. The combination of AI

design tools and integrated cooking capabilities opens possibilities for

automated commercial food production. The system's energy efficiency

and compact size make it practical for restaurants and bakeries seeking

to offer customized food items without extensive technical training. The

researchers envision particular value in healthcare settings, where

precise control over ingredients and portions is crucial. The technology

could enable automated production of specialized diets while ensuring

consistent quality and safety. Their work also demonstrates broader

applications for integrated heating in 3D printing. The precise

temperature control and energy efficiency achieved through their LIG

heating system could benefit manufacturing processes beyond food

production. The integration of AI design capability with real-time

cooking represents a significant step toward accessible automated food

production. By addressing both the technical and usability challenges

that have limited adoption of 3D food printing, this system offers a

practical path toward more automated, customizable food service

operations while maintaining high standards for safety and quality. The

development signals a shift in how commercial kitchens might approach

personalized food production, suggesting a future where complex custom

food items can be created safely and efficiently without specialized

technical knowledge.

No comments:

Post a Comment